Thaum nws los txog rau kev ua kom muaj txiaj ntsig zoo tshaj plaws thiab lub neej ntev ntawm koj cov tshuab, kev xaiv cov saw hlau yog qhov tseem ceeb. Cia peb dhia mus rau hauv cov ntsiab lus tseem ceeb ntawm cov ntaub ntawv, qhov ntev, cov qauv, thiab kev saib xyuas uas yuav tsa koj cov haujlwm mus rau qhov siab tshiab.

Kev Xaiv Khoom SivThaum nws los txog rau kev ua kom koj cov txheej txheem kho tshuab zoo dua, kev xaiv cov khoom siv saw hlau yog qhov tseem ceeb heev. Koj xav kom ntseeg tau tias cov hniav ntawm koj cov sprockets muaj lub zog tiv taus kev nkees thiab kev hnav tsis kam. Yog vim li cas cov hlau carbon zoo, xws li 45 hlau, feem ntau yog qhov kev xaiv mus-rau. Rau cov ntawv thov tseem ceeb, xav txog kev hloov kho dua tshiab rau cov hlau sib xyaw xws li 40Cr lossis 35SiMn rau kev ua tau zoo dua.

Feem ntau cov hniav sprocket raug kho cua sov kom ua tiav qhov nyuaj ntawm 40 txog 60 HRC, kom ntseeg tau tias lawv tuaj yeem tiv taus qhov nyuaj ntawm kev ua haujlwm. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias cov sprockets me me koom nrog ntau zaus dua li lawv cov neeg sib tw loj dua thiab ntsib kev cuam tshuam ntau dua. Yog li ntawd, cov ntaub ntawv siv rau cov sprockets me me yuav tsum zoo dua li cov uas siv rau cov loj dua.

Rau cov sprockets uas yuav tsum tau nyiaj dhau qhov kev co, cov hlau uas tsis muaj carbon yog qhov kev xaiv zoo heev. Ntawm qhov tod tes, cov hlau cam khwb cia yog qhov zoo tagnrho rau cov sprockets uas muaj kev hnav tab sis tsis ntsib kev co hnyav. Yog tias koj daim ntawv thov xav tau lub zog siab thiab kev tiv thaiv kev hnav, cov hlau alloy yog txoj hauv kev mus.

Kev nqis peev rau cov khoom siv zoo rau koj cov saw hlau tsis yog tsuas yog ua kom lawv lub neej ntev xwb tab sis kuj ua rau koj cov txheej txheem ua haujlwm tau zoo dua. Tsis txhob txo qhov zoo - xaiv qhov zoo thiab saib koj qhov kev ua tau zoo nce siab!

Qhov Loj Tseem Ceeb thiab Kev Xaiv Cov Qauv

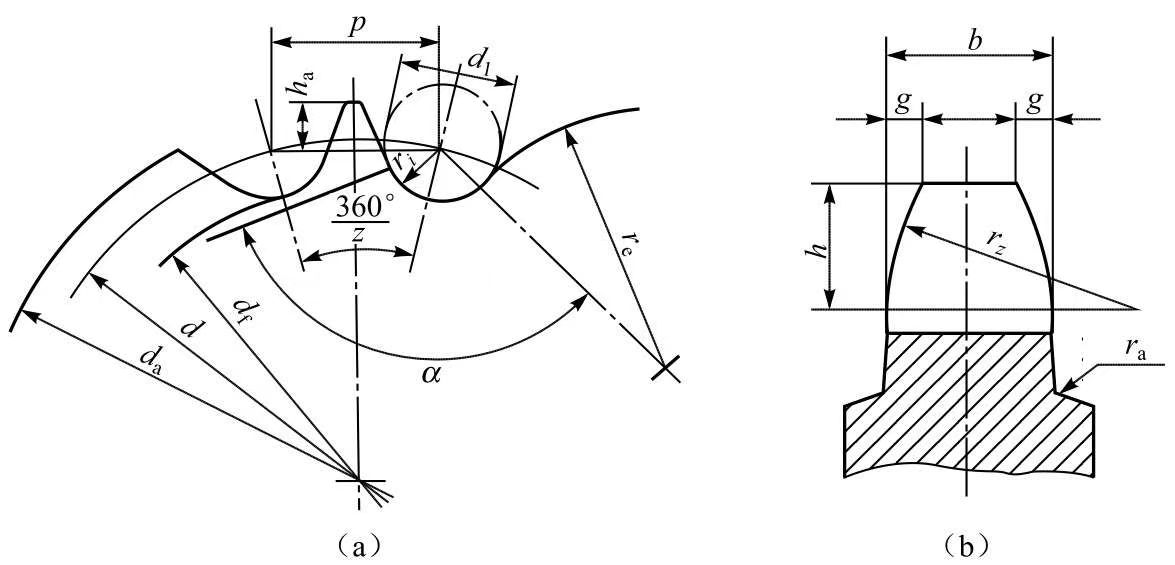

Kev nkag siab txog qhov loj me ntawm koj cov sprockets yog qhov tseem ceeb rau kev ua haujlwm zoo tshaj plaws. Qhov loj me tseem ceeb suav nrog tus naj npawb ntawm cov hniav, txoj kab uas hla ntawm lub voj voog pitch, txoj kab uas hla sab nraud, txoj kab uas hla hauv paus, qhov siab ntawm cov hniav saum toj ntawm lub pitch polygon, thiab qhov dav ntawm cov hniav. Lub voj voog pitch yog lub voj voog uas qhov chaw nruab nrab ntawm cov saw hlau nyob, faib sib npaug los ntawm lub pitch saw.Raws li qhia hauv qab no:

Cov sprockets muaj ntau hom qauv, suav nrog cov khoom khov kho, cov khoom perforated, cov khoom vuam, thiab cov khoom sib dhos. Nyob ntawm qhov loj me, koj tuaj yeem xaiv cov qauv tsim nyog: cov sprockets me me tuaj yeem khov kho, cov sprockets nruab nrab feem ntau siv cov qauv perforated, thiab cov sprockets loj feem ntau sib xyaw cov ntaub ntawv sib txawv rau lub nplhaib hniav thiab lub hauv paus, txuas nrog los ntawm kev vuam lossis bolting. Rau cov piv txwv tshwj xeeb, mus saib Goodwill'slub sprocketcov ntawv teev khoom.

Kev Tsim Hniav: Lub Plawv ntawm Kev Ua Haujlwm Zoo

Tus naj npawb ntawm cov hniav ntawm lub sprocket cuam tshuam loj heev rau qhov du thiab lub neej ntev ntawm lub kis. Nws yog ib qho tseem ceeb uas yuav tsum xaiv tus naj npawb ntawm cov hniav kom raug - tsis txhob ntau dhau thiab tsis txhob tsawg dhau. Yog tias muaj ntau dhau ntawm cov hniav tuaj yeem ua rau lub neej ntawm cov saw luv dua, thaum tsawg dhau tuaj yeem ua rau tsis sib xws thiab ua rau muaj kev thauj khoom ntau ntxiv. Txhawm rau kom txo tau cov teeb meem no, nws yog ib qho tseem ceeb kom txwv tus naj npawb tsawg kawg nkaus ntawm cov hniav ntawm cov sprockets me me, feem ntau teeb tsa ntawm Zmin ≥ 9. Tus naj npawb ntawm cov hniav ntawm cov sprockets me me (Z1) tuaj yeem xaiv raws li qhov ceev ntawm cov saw, thiab tom qab ntawd tus naj npawb ntawm cov hniav ntawm lub sprocket loj (Z2) tuaj yeem txiav txim siab siv qhov piv ntawm kev sib kis (Z2 = iZ). Rau kev hnav sib npaug, cov hniav sprocket feem ntau yuav tsum yog tus lej khib.

Qhov Zoo Tshaj Plaws Chain Drive Layout

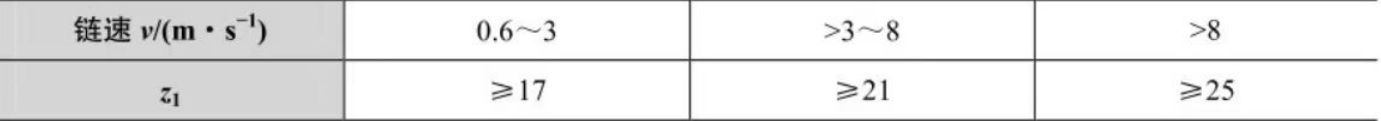

Qhov kev teeb tsa ntawm koj lub saw hlau tsav tsheb tseem ceeb npaum li cov khoom lawv tus kheej. Qhov kev teeb tsa ntawm cov saw hlau tsav tsheb yog qhia hauv qab no

Kev Teeb Tsa Kab Rov Tav: Xyuas kom tseeb tias cov dav hlau tig ntawm ob lub sprockets tau sib phim hauv tib lub dav hlau ntsug thiab tias lawv cov axes sib luag kom tiv thaiv cov saw hlau tsis sib txuas thiab hnav tsis zoo.

Kev Teeb Tsa Ntsug: Khaws lub kaum sab xis ntawm cov kab nruab nrab ntawm ob lub sprocket thiab kab kab rov tav kom me li sai tau, zoo dua tsawg dua 45 °, kom tsis txhob muaj kev sib koom tes tsis zoo ntawm lub sprocket qis dua.

Kev Teeb Tsa Ntsug: Tsis txhob muaj cov kab nruab nrab ntawm ob lub sprockets ntawm lub kaum sab xis 90 °; hloov chaw, teeb tsa cov sprockets sab saud thiab sab qis me ntsis rau ib sab.

Kev Tso Txoj Saw: Tso sab nruj ntawm txoj saw rau saum thiab sab qis rau hauv qab kom tiv thaiv kev poob qis ntau dhau, uas yuav ua rau cuam tshuam rau cov hniav sprocket.

Kev Nruj Rau Kev Ua Haujlwm Zoo Tshaj Plaws

Kev nruj kom zoo ntawm txoj saw hlau yog qhov tseem ceeb heev kom tiv thaiv kev poob qis ntau dhau, uas tuaj yeem ua rau kev sib koom ua tsis zoo thiab kev co. Thaum lub kaum sab xis ntawm ob lub sprockets tshaj 60°, feem ntau siv lub cuab yeej nruj.

Muaj ntau txoj kev rau kev nruj, nrog rau qhov feem ntau yog kho qhov deb ntawm qhov chaw nruab nrab thiab siv cov khoom siv nruj. Yog tias qhov deb ntawm qhov chaw nruab nrab tuaj yeem hloov kho tau, koj tuaj yeem hloov kho nws kom ua tiav qhov nruj xav tau. Yog tias tsis yog, lub log nruj tuaj yeem ntxiv los kho qhov nruj. Lub log no yuav tsum tau muab tso ze rau sab qis ntawm lub sprocket me, thiab nws txoj kab uas hla yuav tsum zoo ib yam li lub sprocket me.

Qhov Tseem Ceeb ntawm Kev Siv Lubrication

Kev siv roj nplua nyeem yog qhov tseem ceeb rau kev ua haujlwm zoo tshaj plaws ntawm cov saw hlau, tshwj xeeb tshaj yog thaum siv ceev ceev thiab hnyav. Kev siv roj nplua nyeem kom zoo yuav txo qhov hnav, txo qhov cuam tshuam, ua kom lub peev xwm thauj khoom ntau dua, thiab ua kom lub saw hlau siv tau ntev dua. Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tsum xaiv txoj kev siv roj nplua nyeem thiab hom roj nplua nyeem kom ua haujlwm tau zoo.

Cov Txheej Txheem Lubrication:

Kev Siv Roj Txhua Hnub: Txoj kev no suav nrog kev siv lub thoob roj lossis txhuam los pleev roj rau ntawm qhov sib txawv ntawm cov phaj txuas sab hauv thiab sab nraud ntawm sab qis ntawm cov saw hlau. Nws raug pom zoo kom ua txoj haujlwm no ib zaug rau ib qho kev hloov pauv. Txoj kev no yog qhov tsim nyog rau cov tsav tsheb tsis tseem ceeb nrog cov saw hlau ceev ntawm v ≤ 4 m / s.

Kev Siv Roj Los Ntawm Cov Khoom Noj: Lub kaw lus no muaj lub plhaub sab nraud yooj yim, qhov twg roj raug ntws mus rau hauv qhov sib txawv ntawm cov phaj txuas sab hauv thiab sab nraud ntawm sab qis los ntawm lub khob roj thiab yeeb nkab. Rau cov saw hlau ib kab, tus nqi roj muab feem ntau yog 5-20 tee ib feeb, nrog rau tus nqi siab tshaj plaws siv ntawm qhov ceev siab dua. Txoj kev no yog qhov tsim nyog rau cov tsav tsheb nrog cov saw hlau ceev ntawm v ≤ 10 m / s.

Kev Siv Roj Da Dej: Hauv txoj kev no, lub plhaub sab nraud uas tsis xau tso cai rau cov saw hlau hla dhau lub thawv roj uas kaw lawm. Yuav tsum ceev faj kom tsis txhob muab cov saw hlau tso rau hauv dej tob dhau, vim tias kev muab cov roj tso rau hauv dej ntau dhau tuaj yeem ua rau cov roj poob ntau vim yog kev sib xyaw thiab ua rau cov roj kub dhau thiab puas tsuaj. Feem ntau pom zoo kom muab cov roj tso rau hauv dej tob li 6-12 hli, ua rau txoj kev no haum rau cov tsav tsheb uas muaj qhov ceev ntawm v = 6-12 m/s.

Kev Siv Roj Rau Hauv Cov Khoom Siv Splash: Cov txheej txheem no siv lub thawv kaw uas cov roj raug splash los ntawm lub phaj splash. Tom qab ntawd cov roj raug xa mus rau cov saw hlau los ntawm lub cuab yeej sau roj ntawm lub plhaub. Qhov tob ntawm lub phaj splash yuav tsum tswj hwm ntawm 12-15 hli, thiab qhov ceev ntawm lub phaj splash yuav tsum tshaj 3 m/s kom ntseeg tau tias muaj kev siv roj zoo.

Kev Siv Lub Tshuab Roj Siab: Hauv txoj kev no, roj raug txau rau ntawm cov saw hlau siv lub twj roj, nrog rau lub nozzle nyob rau ntawm qhov chaw uas cov saw hlau koom nrog. Cov roj uas ncig tsis yog tsuas yog roj xwb tab sis kuj muab cov txiaj ntsig txias. Cov roj muab rau txhua lub nozzle tuaj yeem txiav txim siab raws li qhov siab ntawm cov saw hlau thiab qhov ceev los ntawm kev saib cov phau ntawv qhia cuam tshuam, ua rau txoj kev no haum rau cov tsav tsheb muaj zog siab nrog cov saw hlau ceev ntawm v ≥ 8 m / s.

Yuav kom ua tiav qhov kev ua tau zoo tshaj plaws thiab ua haujlwm tau zoo hauv koj cov txheej txheem kho tshuab, nws yog ib qho tseem ceeb kom nkag siab txog cov ntsiab lus tseem ceeb ntawm kev xaiv thiab kev saib xyuas cov saw hlau. Tsis txhob cia qhov kev vam meej ntawm koj cov tshuab ua rau muaj kev pheej hmoo - txiav txim siab paub zoo uas ua rau muaj txiaj ntsig ntev!

Kev xaiv cov ntaub ntawv, qhov loj me, thiab cov tswv yim txij nkawm yog qhov tseem ceeb rau kev ua kom koj cov haujlwm khiav tau zoo thiab ua tau zoo. Los ntawm kev muab qhov tseem ceeb rau cov yam no, koj tuaj yeem txhim kho lub neej ntev thiab kev ntseeg siab ntawm koj cov khoom siv.

Yog tias koj muaj lus nug txog sprockets lossis xav tau kev qhia ntawm cov kws tshaj lij, thov tsis txhob yig tiv tauj peb ntawmexport@cd-goodwill.comPeb pab neeg mob siab rau peb nyob ntawm no los pab koj nrog txhua yam koj xav tau ntawm sprocket!

Lub sijhawm tshaj tawm: Kaum Ib Hlis-21-2024